The Art of Long-Term Mine Planning

Long-term mine plans don’t fail because of one bad assumption.

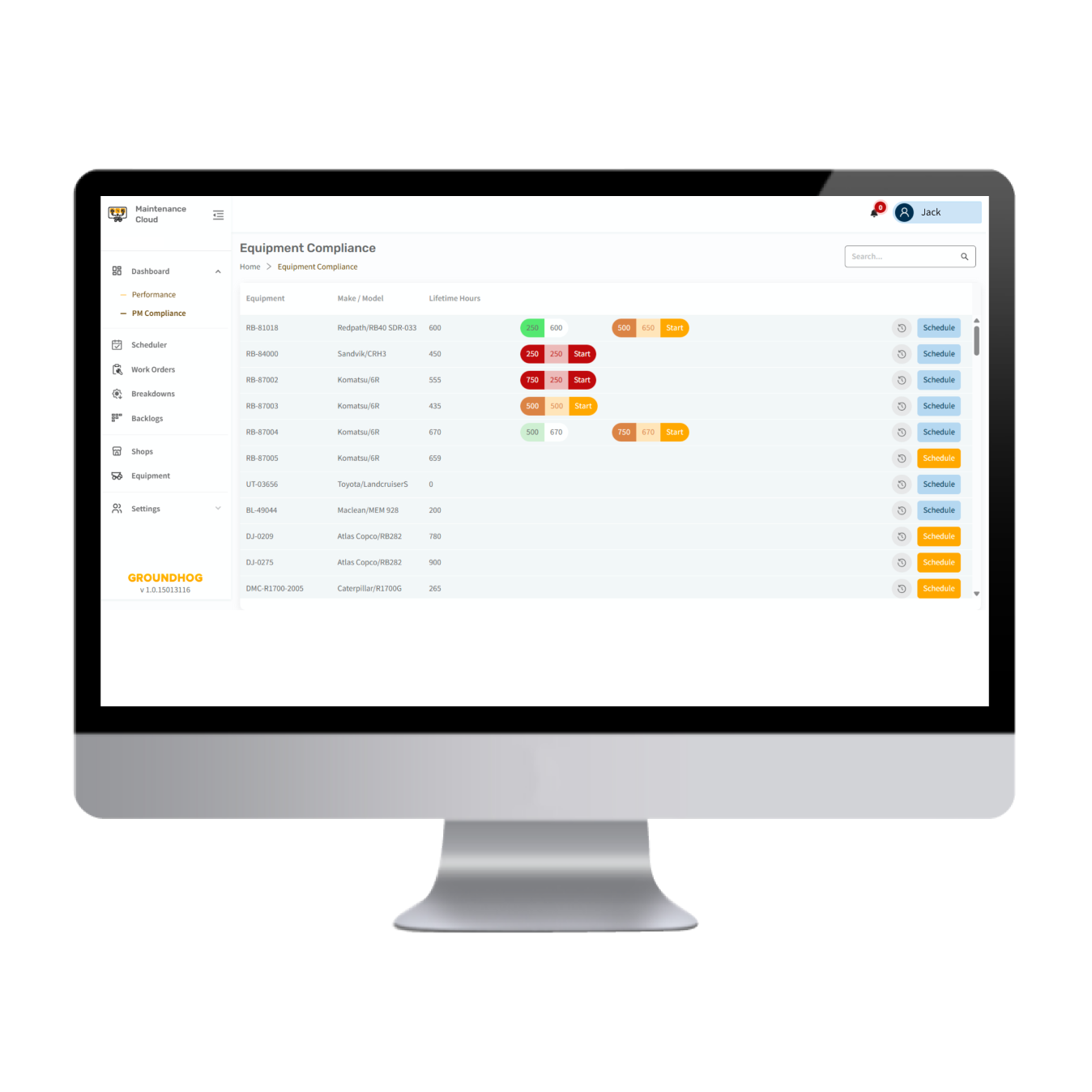

Use GroundHog’s CMMS to effortlessly schedule and manage 250hr, 500hr, and 700hr service intervals—reducing unplanned downtime and keeping your fleet running smoothly.

Prevent costly equipment failures by planning recurring maintenance tasks using a modern CMMS designed for the mining industry.

With GroundHog’s mining-specific CMMS, you can automate maintenance intervals based on equipment usage—minimizing guesswork, paperwork, and the risk of unexpected downtime.

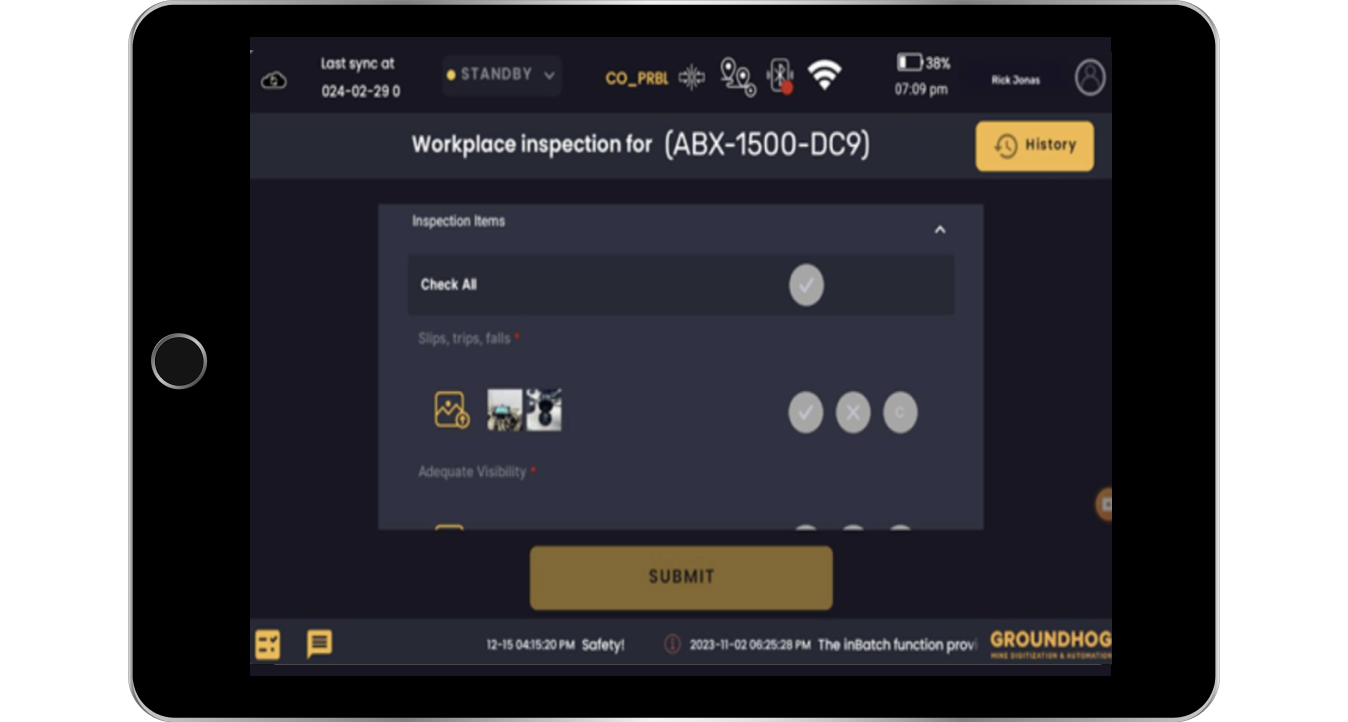

Field teams get real-time access to PM tasks from their mobile devices—even offline—so nothing falls through the cracks.

Technicians can access assigned PM tasks directly from the GroundHog mobile app—even in remote or offline locations. Our CMMS ensures they have everything they need to perform services accurately and on time.

Every PM event is logged, analyzed, and visualized—so you can continuously improve reliability, availability, and compliance.

All PM activity is logged in the GroundHog CMMS, giving you full visibility into what’s working, what’s not, and where your maintenance strategy can improve.

Explore Proven Strategies for Automating PM Tasks, Avoiding Failures, and Extending Equipment Life

Read Related Blogs and Access Useful Links

Long-term mine plans don’t fail because of one bad assumption.

In the first half of 2025, MSHA issued over 43,000

In the first half of 2025, MSHA issued over 43,000

Preventive Maintenance Scheduling is the process of planning and executing maintenance tasks at regular intervals—such as every 250, 500, or 700 hours—to keep equipment running reliably and avoid unexpected breakdowns. GroundHog’s CMMS automates this scheduling based on real-time data.

GroundHog’s CMMS automatically tracks engine hours, usage metrics, and calendar dates to trigger PM tasks. It assigns these tasks to technicians, ensures parts availability, and logs every service in your maintenance history—keeping your fleet in peak condition.

Yes. You can configure maintenance schedules based on engine hours, days, distance, fuel usage, or any custom meter reading—making it ideal for mixed fleets across open-pit and underground operations.

Absolutely. Technicians can view, complete, and document PM tasks using GroundHog’s mobile-first CMMS—even while offline. The app includes checklists, images, and service history to ensure accuracy in the field.

Yes. GroundHog sends automated alerts to planners and technicians when a PM service is approaching. You can also view upcoming tasks in dashboards or generate reports for better planning.

PM schedules are tightly integrated with work orders, parts inventory, and telemetry. When a PM task is triggered, the system automatically checks for required parts and assigns a technician—reducing administrative work and downtime.

Definitely. By proactively servicing equipment based on real-world usage data, you minimize the risk of unexpected failures—resulting in higher uptime, fewer emergency repairs, and longer equipment life.